My second Prusa i3Mk3S (Prusa B) had another restricted movement event. The Y-Axis became stiff and jammed causing a crash detected print fail.

Update 2021-01-24: I contacted Prusa Customer Service with the details and photos of the bearing issues. Prusa sent me replacement bearings: good customer service!

Y-Axis

Symptoms

- Y-Axis stiff.

- Failed Print.

- Crash detected.

Diagnosis

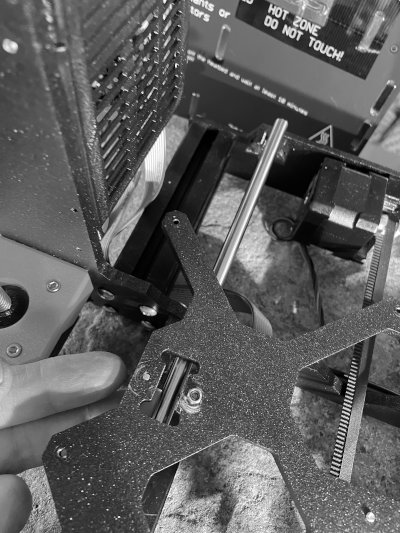

- Removed:

- Build plate

- Heated bed.

- Checked bearings: Left two bearings running rough and stiff.

- Bearing seal debris underneath printer again!

Bearing seal spoor, running rough, stiff: probably two defective bearings.

Treatment

With the heated bed already removed after diagnosis:

- Removed bearings:

- Cut Rail tie-wrap at the rear end,

- Tilted the rail

- Loosened the u-bolts (from each u-bolt: one nut removed completley, the other slacked), and

- Slid off the bearings.

- Replaced bearings:

- Cleaned Rail,

- Slid on the two new bearings,

- Positioned them,

- Re-tightened the u-bolts,

- Tie-wrapped the rail.

- Slid the Y-Axis about a bit to make sure that all seemed correct.

- Re-tightened the Y-Axis belt adjuster as I felt that this was a little slack.

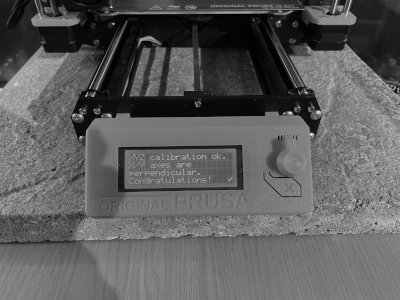

- Calibration -> Wizard: all OK.

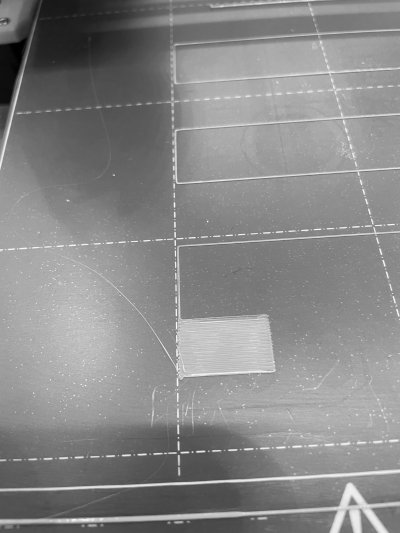

- Calibration -> First layer cal.

Note: I did as little work as possible. It could be more correct to fully remove the heated bed and rail to avoid damage to the printer. I also did not remove the Right-hand rail, or replace the Right-hand bearing. My method worked but it may not be the best engineering practice.

I used the Z adjust value that I had last used and it came out ok.

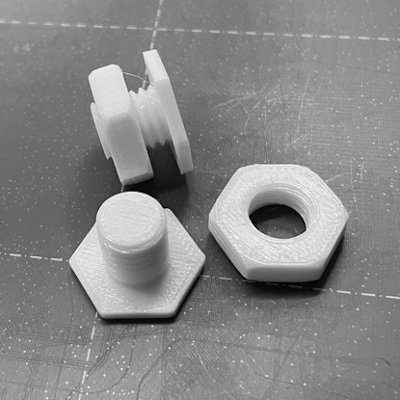

First print: M10 nuts and bolts, 0.4 nozzle, 0.2 layer height (thread test an 0.2), PET-G, Amazon Filament. Printed OK.