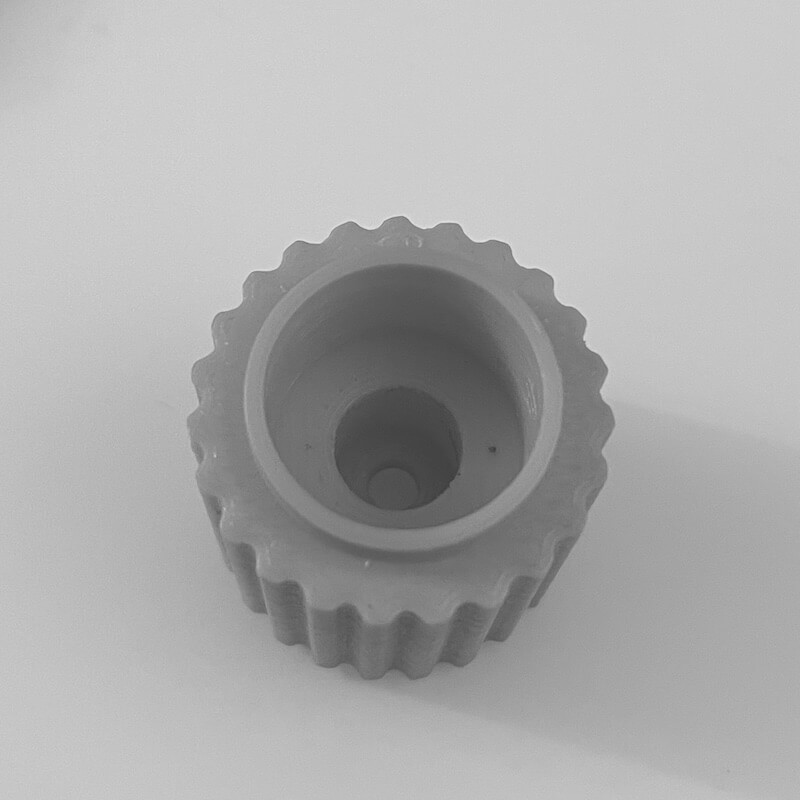

Designing and printing a replacement water filter tap. Not the hardest of tasks. If you are new to 3d printing this may give you some ideas about how to solve your own functional printing needs.

itch

The chrome coating on the injection molded water filter tap has been peeling off for a while. Sharp edges, these have. It cut me again yesterday for the last time!

scratch

- Fire up FreeCAD and designed a replacement tap. Looks different but does the same thing.

- Measuring the old tap was a bit tricky because all surfaces are curved but I got close enough on the first design iteration for version 2 to fit and work.

- I refined my design learning from each pass.

- V3 is the final prototype, and knowing me, probably the final print for this.

- Export .obj file.

- Slice in PrusaSlicer.

- Print on one of my Prusa i3Mk3S (Prusa A in this case), 0.6 mm nozzle (for speed: 43 minutes), textured sheet, PLA for prototyping, 9 grams filament used.

- Fit and use.

design points

- Functionally correct.

- Fits on metal tap mechanism using the original screw.

- Recess for existing screw cap.

- Larger diameter, and textured grip to assist disabled user (I may have to increase the diameter again or include a lever in time).